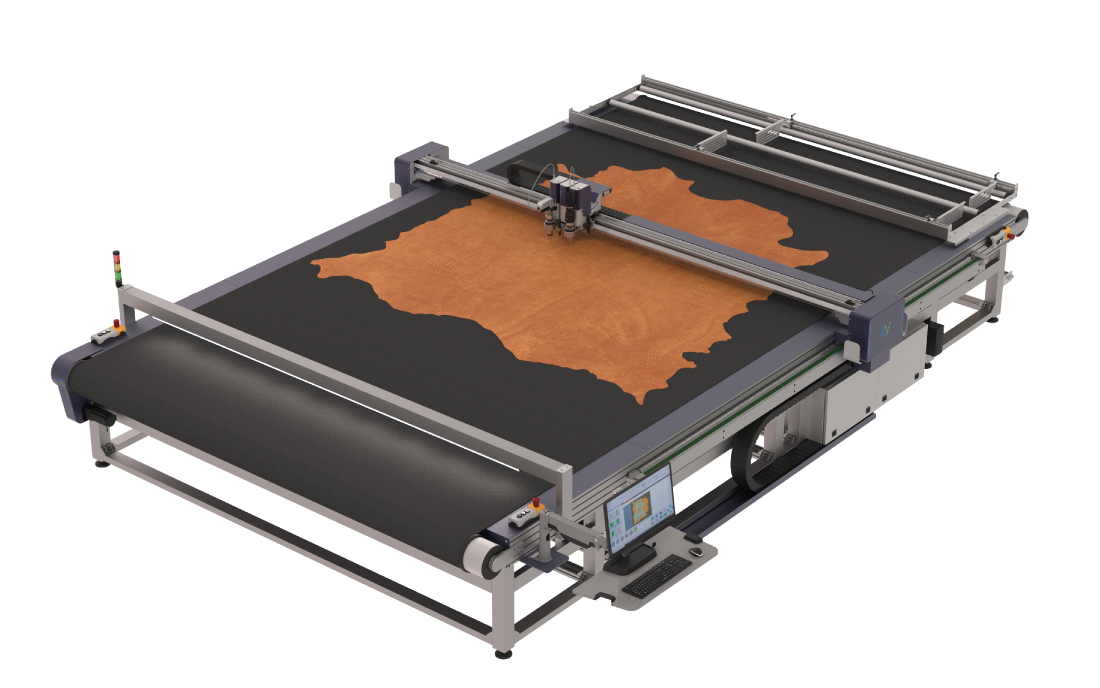

SmartCUT-LF

Versatile. Precise. Unique simplicity of its kind.

The right choice for cutting leather and fabrics. Ideal for industries and workshops.

2 cutting machines in 1 solution.

One machine. Two cutting tools. Endless materials.

With SmartCUT-LF you can meet all your cutting needs thanks to the possibility of cutting both the numerous types of leather on the market and the infinite fabric variations.

This automatic cutting machine is equipped with a front loading area that allows an easy spreading of large whole skins on the cutting area, as well as a cradle for spreading the fabric.

Leather

Fabric

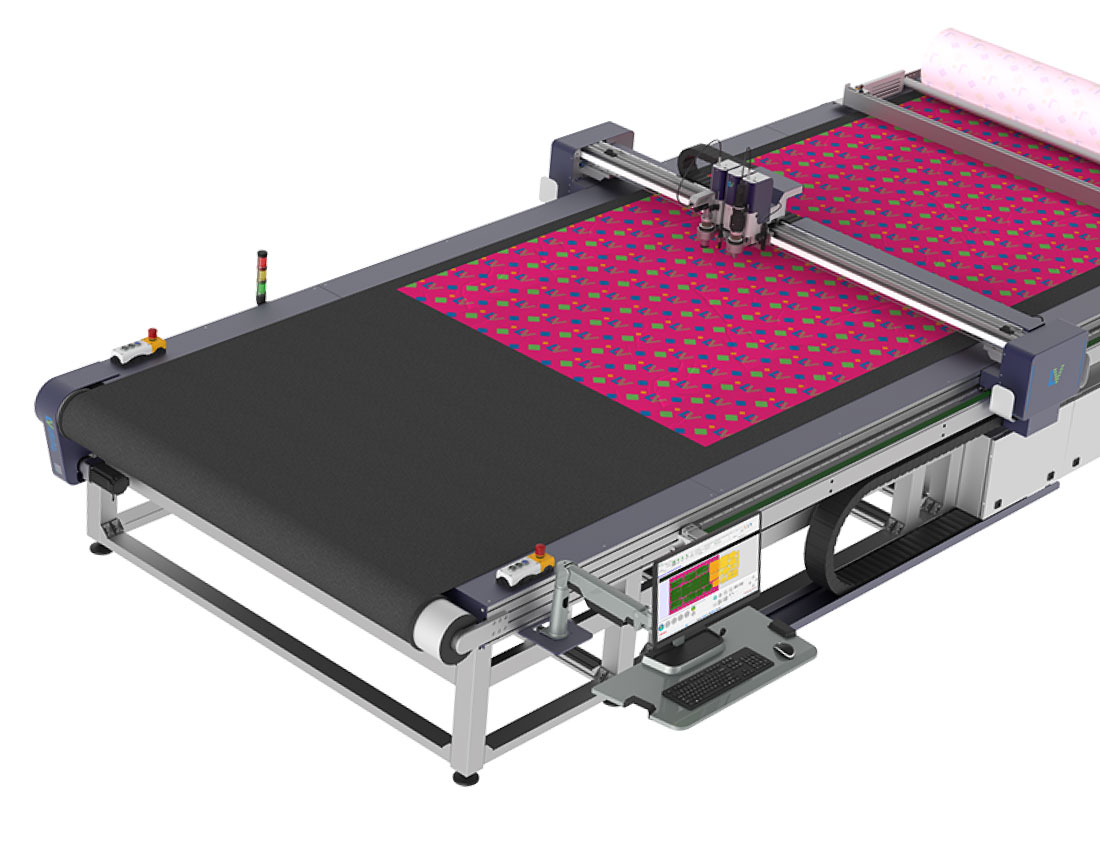

Cuts placements of any length.

Our cutting solutions are equipped with what is called conveyor system.

This means that the machine is equipped with a closed ring belt with the double function of background for cutting (sacrificial material) and means of transporting the material to be cut.

Thanks to this system, the cutting phases are automated, from the loading of the material up to the transport of the cut in the collection area.

This allows, thanks to known advancements controlled by our software, to cut nesting with much longer lengths than the physical length of the useful cutting area of the machine.

The nesting is divided into cutting windows and at the end of each one, an advancement is made and the cutting is resumed passing to the next window. This procedure is repeated until the entire length of the loaded placement is exhausted.

Modularity and customization thanks to the particular construction system

Thanks to the frame construction system using non-welded aluminum profiles, we make the machine’s adaptability to customer needs extremely easy.

SmartCUT-LF is available in different versions and configurations. Do you cut skins or half skins? Based on your needs, we have the opportunity to offer the machine that best suits your needs.

The anodized aluminum frame makes the structure modular, robust, light and with an extremely current and elegant aesthetic.

H

3000

3000

L

3000

2500

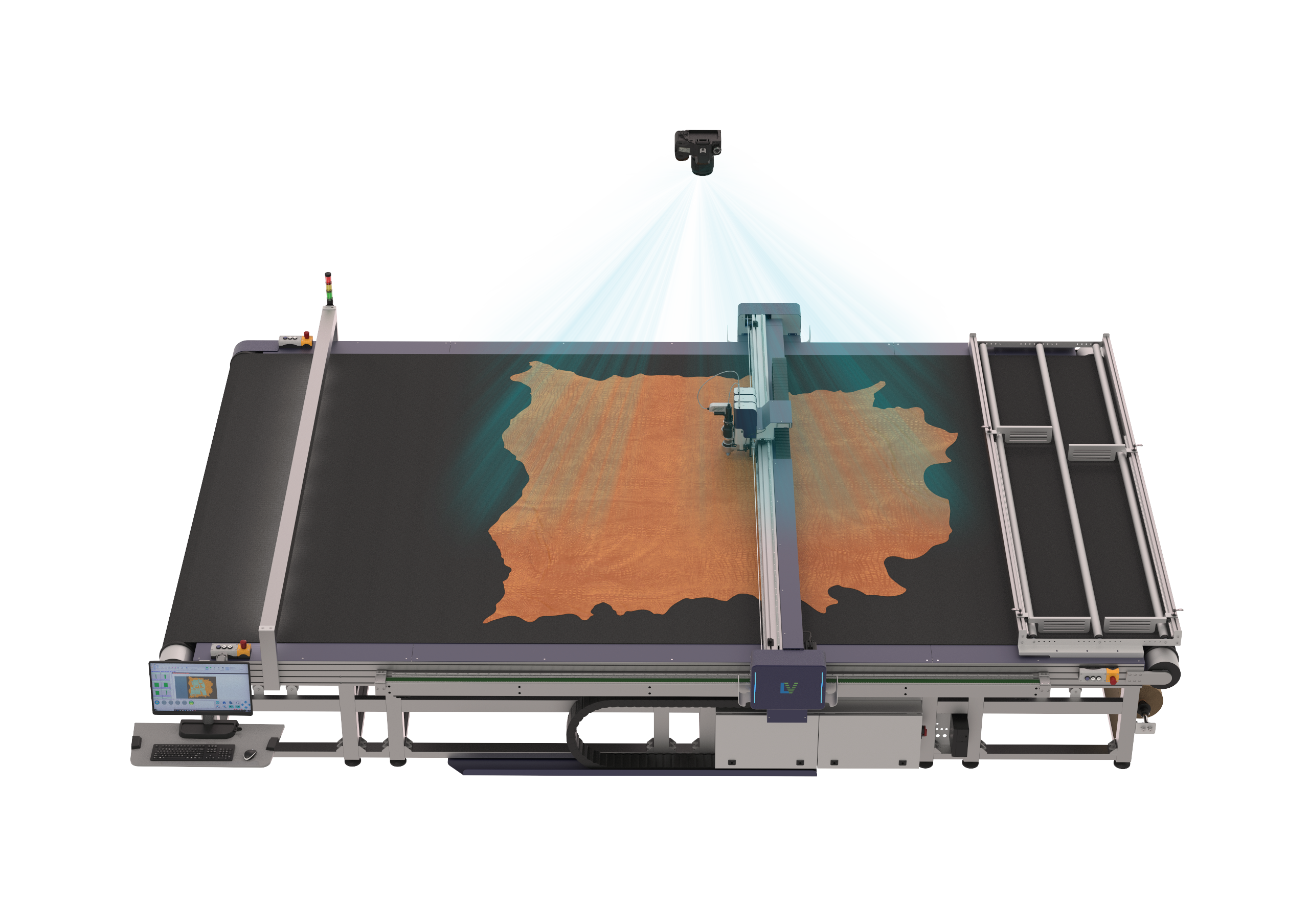

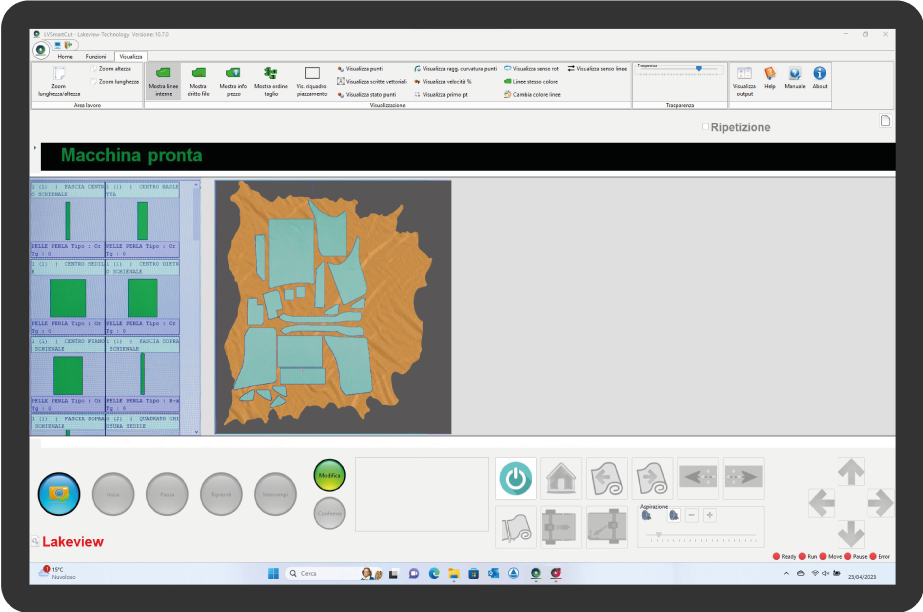

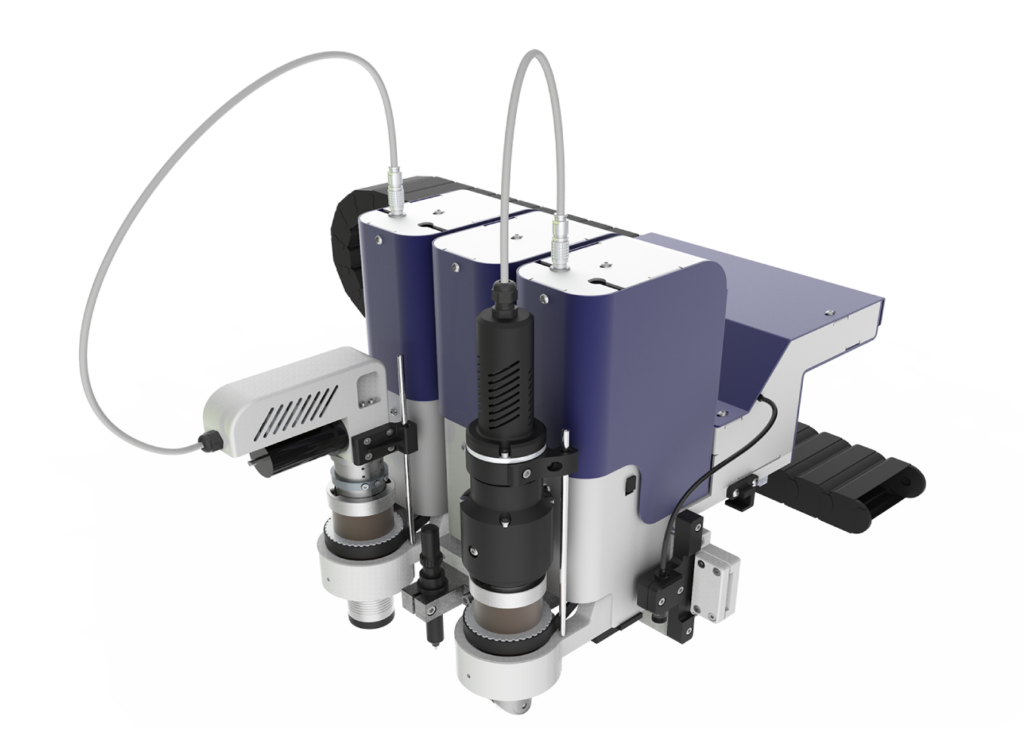

Capture. Match. Cut.

SmartCUT-LF is equipped with a photographic system through which the operator can position the pieces / nesting on the leather or fabric directly via PC.

The system takes a picture of the cutting plane on which the leather / fabric has previously been laid.

The picture, straightened by our algorithm, is displayed on the screen and from here the operator works to arrange his own pieces to be cut by simply using the mouse.

ViewMatch is the simplest, fastest and most effective system for positioning the pieces to be cut.

The numerous features with which the software is equipped will allow you to zoom, match nestings, move or rotate single pieces, modify the cutting sequence and much more …

Cutting will become fun.

ViewMatch

Spreading fabric/leather

Capture

Picture loading/ video match

Cut

Move

Rotate

Zoom

...and many other features...

Precise. Quick. Safe.

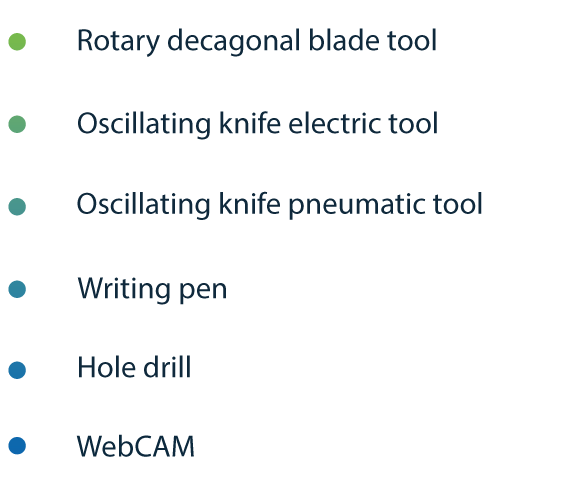

The SmartCUT-LF cutting head is equipped with two precise, quick and extremely reliable cutting tools to meet your every need.

Do you have to cut hard leather? Or maybe a soft skin? Or maybe you need to cut a fabric rather than resin for the padding of your product?

Trust in LVCut.

Thanks to our software, in fact, you can set infinite cutting configurations for each type of material.

Minimum maintenance. Maximum precision.

The SmartCUT-LF cutting head is equipped with 3 tool stations. The two external workstations are capable of housing cutting tools for which movement around their axis is required.

In the specific case, SmartCUT-LF houses a rotating cutting tool with a decagonal blade and an oscillation cutting tool.

The high-speed decagonal blade allows to cut fabrics, resins (under suction) and soft leathers with extreme precision.

The oscillating cutting tool, on the other hand, allows cutting thicker and harder materials such as hide and hard hide that are more difficult to cut.

The central station is able to house optional tools such as the nib to mark pieces or a drill to obtain small holes.

We follow the differences in height for a homogeneous cut.

The entire cutting area, due to its size, can have differences in height. A constant descent of the tool would cause uneven cuts with problems of detachment of the cut pieces.

SmartCUT-LF is extremely intelligent. After an accurate mapping of the cutting plane, thanks to an algorithm developed ad hoc, the machine knows exactly for each cutting coordinate the descent height of the tool to guarantee a constant penetration of the blade into the fabric/leather and the carpet to ensure a continuous, precise and homogeneous cut.

This particular feature also allows a considerable reduction in wear of consumable parts.

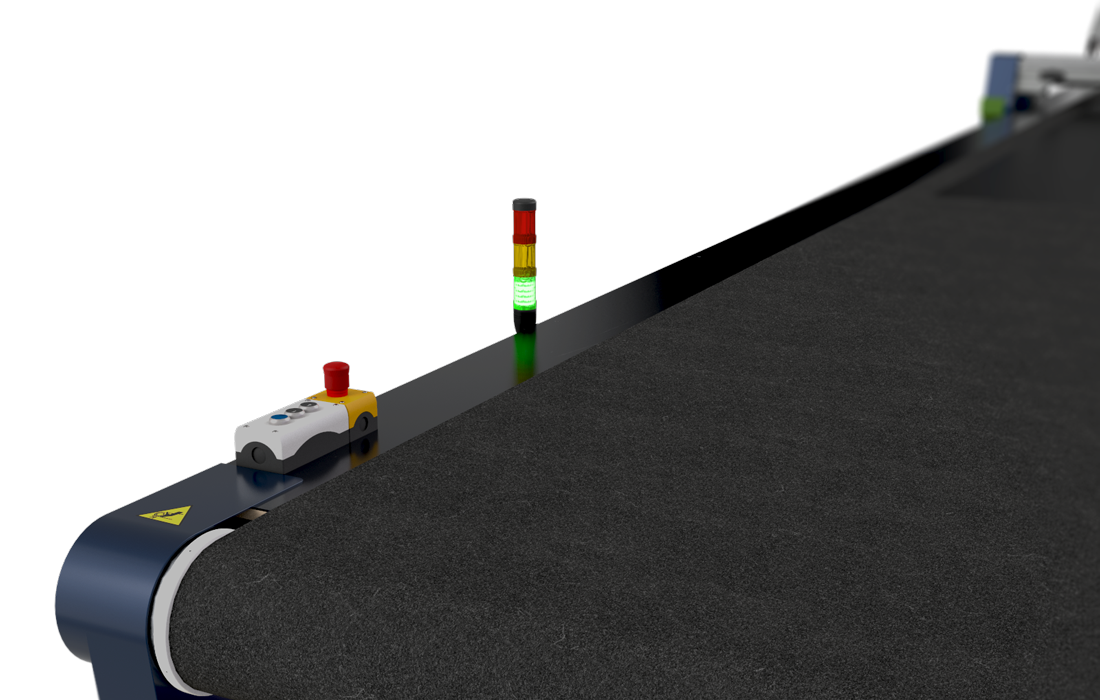

We always think about the safety of those who work.

SmartCUT-LF is extremely secure. The operator is constantly protected from the operating movements of the machine thanks to automatic stop systems in case of interference between the machine body and the operator.

The beam is equipped with a double photoelectric sensor that crosses the entire width of the machine body. The positioning of these sensors on the front and rear allows immediate shutdown of operations in the event of an external body crossing the light ray.

The same principle is adopted for stopping in the event of a collision between the user and the beam on the machine. The cutting head is also protected by a cover carter that prevents access to the cutting bodies.

A sensor positioned on the head, which cannot be bypassed, guarantees the start of cutting only in protected machine conditions.

Machine complies with safety regulations.

Bright feedback. SmartCUT-LF also stands out from afar.

The machine body is equipped with a 3-color light tower to allow direct feedback of the operating status.You will immediately notice, even remotely, of any machine lockouts or the need for user intervention.

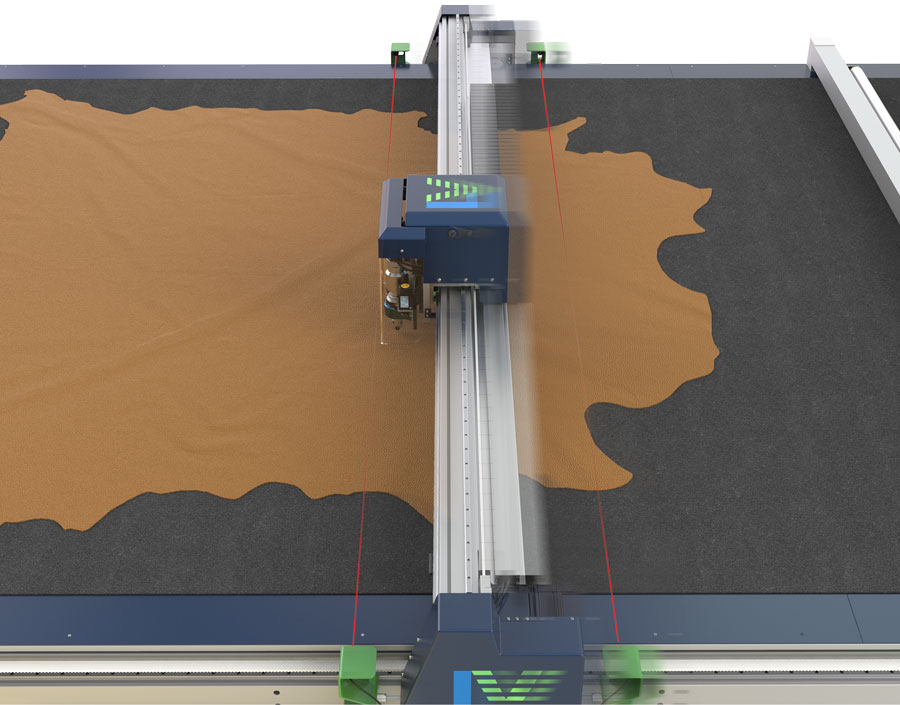

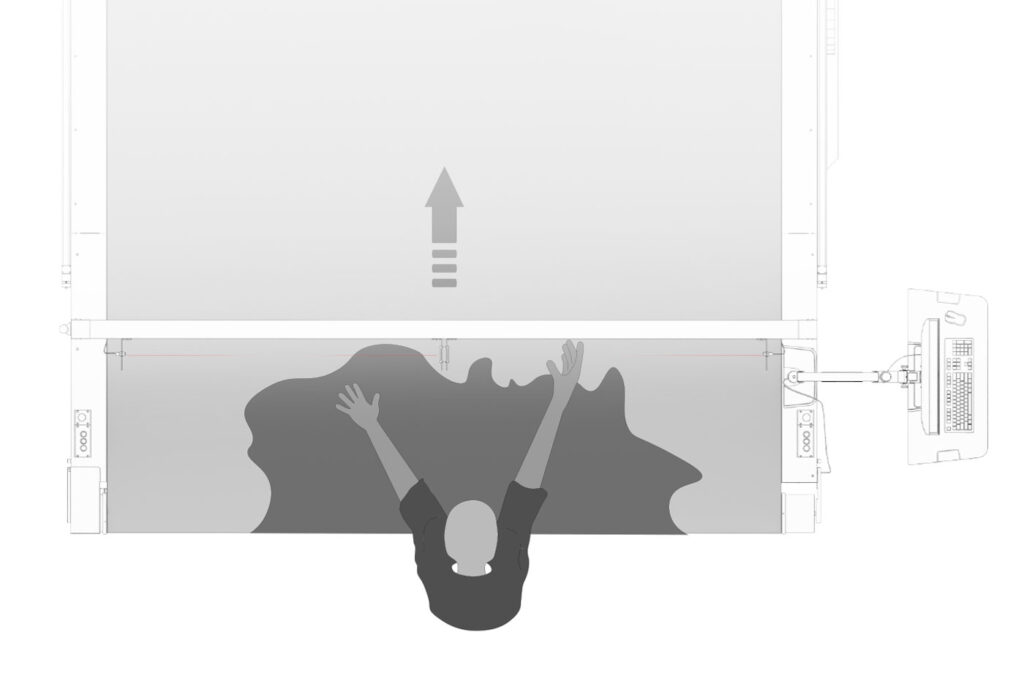

Extremely simple leather loading thanks to the innovative photoelectric control system.

Thanks to the innovative photoelectric sensor system, the operator can manage leather loading with ease.

The width of more than 3 meters of the machine would require user movements to reach the forward and backward pushbuttons of the carpet placed on the two sides of the frame.

This special system allows to carry out this operation from any position by simply barring the light ray passing between the emitter and reflector.

The interruption of the ray (right for advancement and left for retraction) sends a signal to the control board allowing the carpet to be activated in the desired direction.

In this way, the user, without ever having to move, can concentrate on loading with maximum concentration for a simple, fast and safe result.

Defect ... don't run away!

SmartCUT-LF is equipped with a natural-light LED lamp that allows you to illuminate the leather with the aim of highlighting defects.

In this way, the operator, during the drafting operation, can mark defects or quality areas with the utmost accuracy thanks to the focused lighting along the entire opening of the machine. Marked defects will then be displayed directly on the screen thanks to the ViewMatch system.

The user can therefore position the pieces to be cut extremely quickly and precisely, avoiding areas of low quality or with the presence of defects.

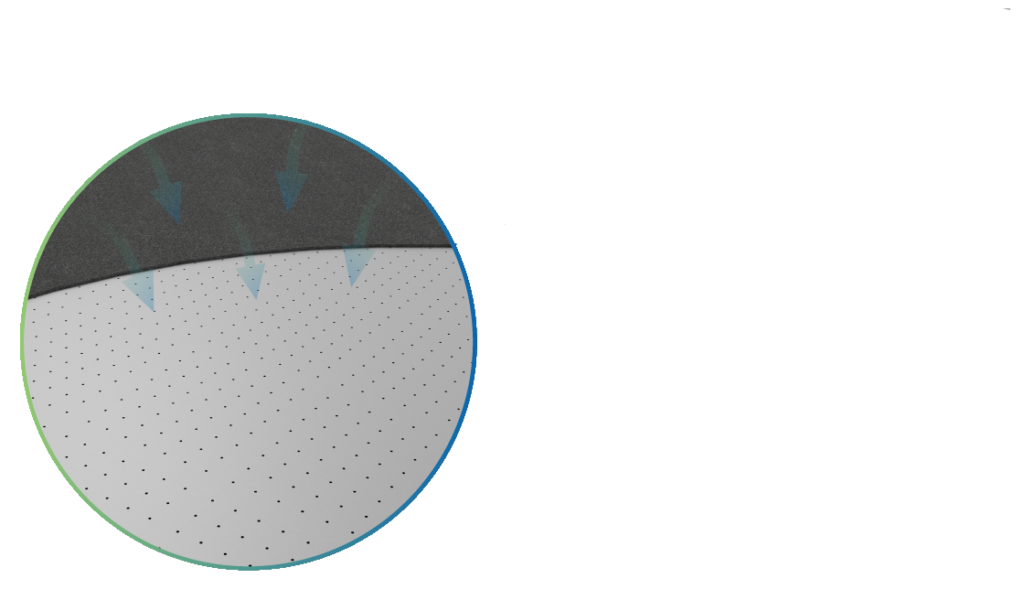

Suction table for better grip

Most of the fabrics, thanks to the grip with the carpet, remain sufficiently adherent to the surface without the risk of these moving during the cut.

In some cases, due to the physical characteristics of the material, greater material-level adhesion is required.

SmartCUT-LF is equipped with a suction box underneath the entire cutting area, the upper surface of which is equipped with micro-holes which allow the suction of the material, increasing its grip thus allowing the maximum cutting quality without incurring any risks of any kind .

The turbine with which the machine is equipped, despite its power, produces extremely low noise, in compliance with the regulations for work environments with personnel operating without ear protection.

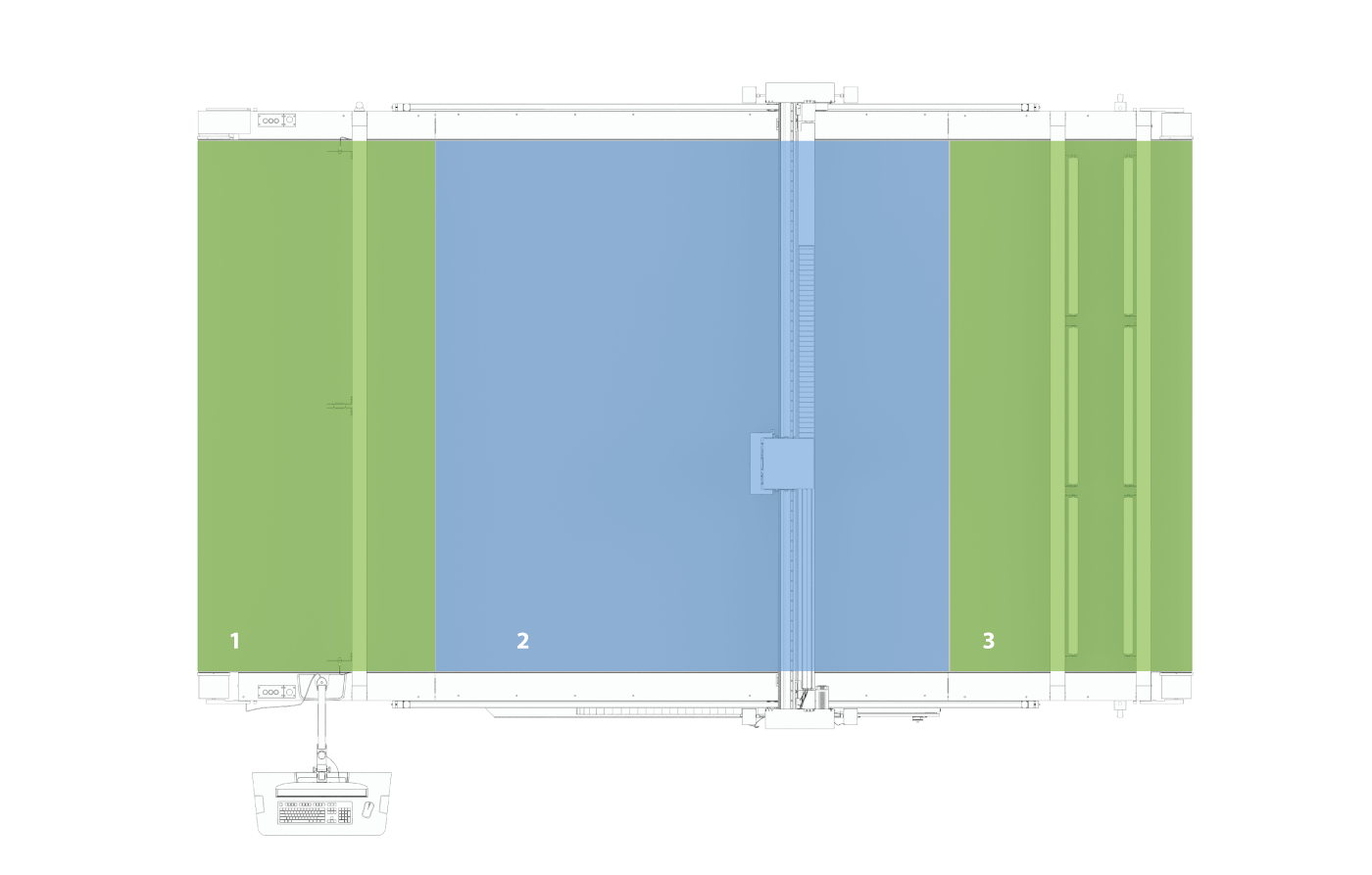

Just the way I am

1. Loading area

2. Cutting area

3. Collecting area / leather loading

*The dimensions indicated refer to a machine with a cutting area of 3000mmx3000mm